ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

The CNC lathe's ability to perform complex operations with high speed and accuracy enables manufacturers to produce parts quickly and efficiently, reducing production time and costs.

Max. Swing over Bed : Φ1000mm

Max. Swing over slide : Φ650mm

Max. turning length : 1m~3m

| Name | Unit | Specifications | ||||

| CK61100/1000 | CK61100/1500 | CK61100/2000 | CK61100/3000 | |||

| Max. Swing Over Bed | mm | Φ1000 | Φ1000 | Φ1000 | Φ1000 | |

| X-Direction Rail Span | mm | 330 | 330 | 330 | 330 | |

| Z-Direction Rail Span | mm | 600 | 600 | 600 | 600 | |

| Max. Swing Over Slide | mm | Φ650 | Φ650 | Φ650 | Φ650 | |

| Top Distance | mm | 1000 | 1500 | 2000 | 3000 | |

| Max. Disc Machining Diameter | 1000 | 1000 | 1000 | 1000 | ||

| Max. Turning Length | mm | 1000 | 1500 | 2000 | 3000 | |

| Center High | From the bed | mm | 500 | 500 | 500 | 500 |

| From The Ground | mm | 1260 | 1260 | 1260 | 1260 | |

| Spindle Through Hole Diameter | mm | φ105(optionalφ130) | ||||

| Bar Diameter | mm | φ104 | φ104 | φ104 | φ104 | |

| Optional Hollow Chuck Pull Rod Through Hole | mm | φ88 | φ88 | φ88 | φ88 | |

| Spindle End Type | A2-11 | A2-11 | A2-11 | A2-11 | ||

| Chuck | mm | φ400 | φ400 | φ400 | φ400 | |

| Spindle Taper Hole Taper | No | Metric 120,

1:20 |

Metric 120,

1:20 |

Metric 120,

1:20 |

Metric 120,

1:20 |

|

| Spindle Limit Speed | rpm | 30-84,53-150,125-350,300-835r/min

Manual four-speed, infinitely variable speed within the gear |

||||

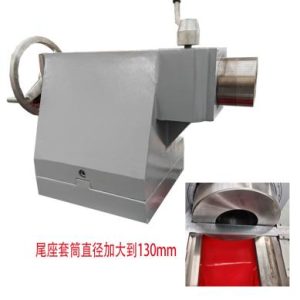

| Tailstock Sleeve Diameter | mm | φ130 | φ130 | φ130 | φ130 | |

| Tailstock Sleeve Bore Taper | No | MT6# | MT6# | MT6# | MT6# | |

| Tailstock Sleeve Travel | mm | 265 | 265 | 265 | 265 | |

| Tailstock Form | Ordinary hand crank | Ordinary hand crank | Ordinary hand crank | Ordinary hand crank | ||

| Number Of Electric Tool Holders | Pcs | 4 | 4 | 4 | 4 | |

| Knife Square Size | mm | 32×32(four stations) | 32×32(four stations) | 32×32(four stations) | 32×32(four stations) | |

| Screw Model | X direction | FYND3206-3-P3 | FYND3206-3-P3 | FYND3206-3-P3 | FYND3206-3-P3 | |

| Z Direction | FYND6310-5-P4 | FYND6310-5-P4 | FYND6310-5-P4 | FYND6310-5-P4 | ||

| X/Z Direction Rapid Movement Speed | m/min | 4/5 | 4/5 | 4/5 | 4/5 | |

| X Travel | mm | 435 | 435 | 435 | 435 | |

| Z Travel | mm | 1000 | 1500 | 2000 | 3000 | |

| Minimum Setting Unit | mm | 0.001 | 0.001 | 0.001 | 0.001 | |

| Main Motor Power | KW | 15(variable frequency) | 15(variable frequency) | 15(variable frequency) | 15(variable frequency) | |

| X/Z Axis Motor Twist | N.M | 10/15 | 10/15 | 10/22 | 10/30 | |

| Total Power | KW | 18 | 18 | 20 | 22 | |

| Net Weight Of Machine Tool | Kg | 5000 | 5500 | 6000 | 7200 | |

| Dimensions (Length X Width X Height) | mm | 3500x2000x2000 | 4000x2000x2000 | 4500x2000x2000 | 5500x2000x2000 | |

1. CK61100 is a mature product for export. The whole machine has compact structure, beautiful and pleasant appearance, large spindle torque, high rigidity, stable and reliable performance, and excellent precision retention.

2. The optimized design of the bed head box is suitable for the turning processing of discs and shafts. It can process straight lines, arcs, metric and inch threads, and multi-start threads. It is suitable for turning discs and shafts with complex shapes and high precision requirements. Class parts processing.

3. The guide rails of the machine tool and the slide saddle guide rails are all made of special material hard guide rails. After high-frequency quenching, they are super hard and wear-resistant, durable and maintain good machining accuracy.

|

Spindle

High-quality steel die forging normalizing processing quenching and tempering semi-finishing high frequency precision machining-finished products. The high-precision spindle bearing group has been precisely assembled and dynamically balanced to ensure high precision, low noise and strong rigidity of the spindle. |

|

Tool holder

Using worm gear transmission, three-toothed disc meshing positioning, screw locking principle, stable indexing, no lifting, avoiding cutting fluid seeping into the tool holder during indexing. |

|

Chuck

K11 series three-jaw self-centering chuck, short cylindrical connection, integral jaws (one pair of front and back), K11A/C/D type jaws are separated jaws, which can be adjusted to be used as positive jaws and reverse jaws. |

|

Transmission

Screws and nuts are processed, ground, assembled and quality controlled in a constant temperature workshop to ensure their high precision and stability. |

|

Tail stock

At the other end of the main shaft, after moving to a certain position, loosen the locking handle, turn the hand wheel to move the sleeve, push the workpiece tightly, and then lock the sleeve to perform turning. |

|

Machine tool lubrication

RBCLB-3ZK positive displacement lubricating pump, automatic lubricating, mainly supplying oil uninterruptedly to the lubricating surface between the guide rail of the bed and the dovetail surface of the carriage, and the lubricating surface between the ball screw and the nut. |

Standard accessories:

| Name | Specifications | Quantity | Supplier |

| Control System | GSK 988TDI | 1 set | China |

| Spindle motor | 15 KW Variable frequency | 1 set | China |

| Spindle structure | Precision Assembled | 1 set | China |

| Spindle bearing | NN3032K/W33P5;234432M/SP

NN3026K/W33P5 |

1 set | China |

| Guide | Hard rail | 1 set | China |

| X Direction ball screw | FYND3206 | 1 set | China |

| Z Direction ball screw | FYND6310 | 1 set | China |

| X Direction screw bearing | BS2562/P4DB;6205 | 1 set | Japan |

| Z Direction screw bearing | BS4090/P4TBT;BS4090/P4DT | 1 set | Japan |

| Tool holder | HAK-21280 | 1 set | China |

| Automatic lubricating device | RBCLB-3ZK | 1 set | China |

| Three-jaw manual chuck | K11400 | 1 set | China |

| Cooling pump | 1 set | China |

Optional accessories

| Name | Specifications | Quantity | Supplier |

| Hydraulic station (optional) | 43L | 1 set | China |

| Hydraulic chuck (optional) | 8” inch | 1 set | China |

Youtube Channel : Antishicnc Machine