ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

CNC lathe has now become the ideal choice for manufacturing to process all kinds of precision parts, it can be in accordance with the preset procedures and parameters, fine processing of raw materials, to ensure that each part meets the strict quality standards, has changed the traditional manufacturing production methods and efficiency, and promoted the rapid development of modern manufacturing industry.

In the automotive manufacturing industry, CNC lathes play an important role. Automobiles are composed of a large number of parts, and many key parts such as the engine’s cylinder block, cylinder head, crankshaft, camshaft, and the gear shaft and drive shaft of the transmission require extremely high precision to ensure the performance, reliability and durability of the car. CNC lathes, with their advanced CNC systems and sophisticated mechanical structures, can accurately cut and shape these complex parts, ensuring that each part meets strict standards and meets the high-precision requirements of automotive parts.

In the aviation manufacturing industry, CNC lathes are also indispensable. Various shaft and disc parts of aircraft engines, as well as complex connectors in the fuselage structure, all require CNC lathes for precision machining. Advanced CNC lathe technology can achieve efficient cutting of high-strength alloy materials, manufacture aviation parts with high-precision tolerances and good surface quality, effectively improve the performance and reliability of aircraft engines, reduce the overall weight of aircraft, and improve fuel efficiency and flight safety performance.

|

|

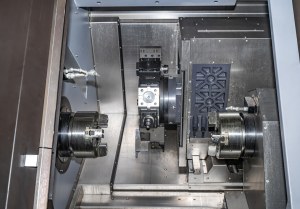

It is worth mentioning that with the continuous development of technology, advanced equipment such as multi-axis linkage CNC lathes and high-speed CNC lathes continue to emerge, further expanding the scope of application of CNC lathes in the field of aerospace. For example, multi-axis CNC lathes can complete the processing of parts with complex spatial shapes at one time, greatly improving the processing efficiency and accuracy; High-speed CNC lathes can complete the processing of a large number of parts in a short time to meet the needs of large-scale production in the aerospace industry.

|

|

With the growing demand for personalized customized products in the manufacturing industry, the flexible processing capability of CNC lathes has also been fully utilized. Enterprises can quickly adjust the CNC lathe processing process through programming to achieve small batch, diversified production mode, whether it is the manufacture of complex medical implants, or custom designed product parts, can meet the various needs of customers, such as in the industrial aviation air pressure, hydraulic and other systems, the demand for sealing rings is large, and it is a wearing part. The precision requirements are more strict, so in order to avoid errors in production, the modern manufacturing industry uses CNC lathes to standardize the production of the seal ring, not only to improve the production efficiency of the seal ring manufacturing, but also to maintain the consistency of product quality, reducing the overall production cost, it can be seen that the importance of CNC lathes in modern manufacturing industry is becoming increasingly prominent.

|

|

Nowadays, intelligent, networked and complex has become an important trend of its future development. The application of advanced sensor technology and intelligent control system enables the CNC lathe to monitor the parameters in the machining process in real time, achieve self-diagnosis and optimization adjustment, and further improve the machining accuracy and efficiency.

In the future, CNC lathe technology will continue to evolve and improve, its performance and function will continue to improve, continue to play an important role in modern manufacturing. Shanghai ANTISHICNC Machinery Equipment Co., Ltd. has been committed to providing advanced and reliable CNC lathe equipment for the manufacturing industry. In the future development road, we will follow the evolution of CNC lathe technology, continue to innovate and optimize products to meet the increasingly demanding needs of the market, and contribute our strength to the high-quality development of the manufacturing industry.

Shanghai ANTISHICNC company has flat bed CNC lathes,slant bed CNC lathes,CNC turning and milling compound machining centers, vertical CNC lathes, horizontal CNC lathes and other structures and models CNC lathe machines.