ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

A.FANUC graphical auxiliary programming function overview

FANUC currently used in the CNC on the graphical auxiliary programming on the function of Manual Guide i, Manual guide 0i, Turn Mate i, the characteristics of these three functions are as follows:

| Manual Guide i | Manual Guide 0i | Turn Mate i | |

| Applicable machine tools | Various types of machine tools (machining centers, lathes, 5-axis machines, mill-turn machines, etc.) | Conventional machine tools (lathes, machining centers) | Simple lathe (X,Z2 axis) |

| Applicable systems | 0i-TD/MD 30i/31i/32i-A 0i F (PLUS) |

0/TD/MD 0iMate-TD/MD 0i F (PLUS) |

0i-TD(1path) 0iMate-TD 0i F (PLUS) |

| Animation simulation | Solid simulation

Tool path simulation |

None (can use graphic function or select another dynamic graphic)

graphic function or an optional dynamic graphic) |

None |

| Setting guide | Work-piece measurement

Tool measurement |

None | None |

| Specification | So far FANUC the highest level, the most comprehensive graphic dialog function, covering from programming to machining, work-piece measurement and other operations of all processes | Dialog programming software dedicated to the 0i series

Dialog programming is possible for fixed cycles and common action combinations. |

Simple definition of the machining process in the form of a graphic dialog for simple lathes, without the need to program the machining process. |

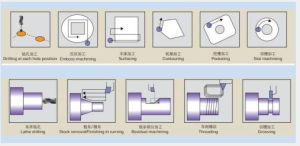

The most powerful of these is Manual Guide i, which can dramatically simplify shop floor programming. The software can assist operators/programmers to complete the conversion of part features to machining programs in a short period of time, greatly improving work efficiency. Using the Manual Guide i function can be easily carried out on the FANUC system turning, milling and multi-machining programming operations, but also can be simulated to verify the machining program.

B.Functionality of Manual Guide i

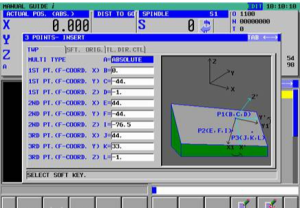

The Manual Guide i software can be applied to T (Turning) and M (Milling) series systems respectively. The internal function module consists of four main sections: Basic Programming Functions, General Information, ISO Programming, and Tooling and Offset Section. The basic programming function module can simulate the three working modes of CNC: EDIT, MEM and JOG, which can complete the functions of program editing and modification, program running and simulation, and manual operation respectively. Among them, the machining simulation process can realize the display of animation and tool trajectory, which is convenient to verify the accuracy of the machining program. The General Information Module and the Tool and Offset Module are mainly for setting the machine coordinate system, machine zero point and tool offset information, so that the program can be prepared more accurately and verified through simulation, and the ISO Programming Module also provides the function of direct ISO programming, and can also add auxiliary function codes directly, which is convenient and easy to use. In addition, Manual Guide i provides a comprehensive screen for the use of measurement functions, including tool measurement, work-piece measurement, and post-machining measurement. With these tools, you can perform basic tool data measurement, work-piece setup, and work-piece in place inspection.

With the continuous upgrading of the CNC system, the Manual Guide software is also constantly being updated. For some functions with high repeatability requirements, they are directly integrated into the software, such as tilting table plane indexing commands, etc., to help users make better use of the CNC functions.

C.the purchase of notes

We must pay attention to the purchase, FANUC system is divided into TYPE 1 , TYPE 3 and TYPE 5 of prices also vary a lot, 5 packages of the system can not be configured manual guide i. Purchasing machine tools can not only look at the manufacturer’s configuration of the system brand, but also pay attention to the type of system package.

Therefore, the procurement of machine tools can not just look at the manufacturer to configure things which manufacturers, for example, Fanuc system, Fanuc system has a package of 3 packages and 5 packages of points, the price also varies a lot.

The same Fanuc motor, and divided into Alpha and Beta motors.

The same is the Mitsubishi M80 system, and is divided into M80A and M80B two models, which is a difference of more than 10,000 dollars. The same is the Mitsubishi 11kw motor, and D11 and DG11 these two motors, the price is a big difference, so choose the machine tool to choose a good machine tool have to go to the finer points, can not just look at the surface.

Another example is the same Taiwan Jianchun BT40-150 spindle, and divided into four and six bearings, both of which have a great price difference.

So the two machine tool manufacturers offer if the accessories are the same family but also to see what specifications of the accessories used, do not be price blindfolded, in the price transparency of society, it is certainly good goods are not cheap cheap no good goods!

If you have the need of CNC lathe, welcome to consult Shanghai ANTISHICNC. We have a wealth of experience in the manufacture and use of lathes, can provide you with professional technical support.

Keywords: lathe, CNC lathe, CNC system