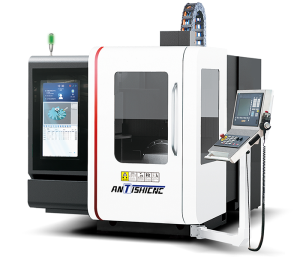

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

Under the background of fierce competition and continuous pursuit of excellence in the global manufacturing industry, the rapid development of science and technology is reshaping the production mode of various industries. Among them, the five-axis vertical machining center, with its excellent processing capabilities and unparalleled high precision characteristics, steadily occupies the core position in many manufacturing fields, provides strong support for a variety of complex and precise manufacturing tasks, and constantly promotes the technological innovation and development of the manufacturing industry.

From the perspective of technical principles, the five-axis vertical machining center has three linear motion axes of X axis, Y axis and Z axis, and two rotating axes of A axis and C axis. The unique five-axis cooperative movement enables the machine tool to complete extremely complex motion trajectories in three-dimensional space, machining a variety of precise three-dimensional surfaces, and realizing multi-angle and multi-direction cutting operations.

Five axis vertical machining center features:

|

High precision |

Multi-axis linkage to achieve accurate machining, can allow the tool to process the workpiece from different angles and directions, can better adapt to the shape of complex parts, to avoid the accumulation of errors that may be caused by multiple clamping or single direction processing, thus greatly improving the processing accuracy. Equipped with high-precision control system, it can accurately control and monitor various parameters in the machining process, such as feed speed, spindle speed, cutting depth, etc. And can feedback the data in the processing process in real time, in order to adjust the processing parameters in time to ensure the stability of the processing accuracy. At the same time, the control system also has the error compensation function, which can compensate the geometric error and thermal deformation error of the machine tool itself, and further improve the machining accuracy. |

|

High efficiency |

With a powerful spindle and drive system, it can provide a high cutting speed and feed speed, greatly reducing the processing time. The five-axis vertical machining center can complete the processing of multiple faces and multiple angles of complex parts through one clamping, avoiding the time waste and error risk caused by multiple clamping. This not only reduces the number of clamping times and auxiliary time, but also improves the consistency and consistency of the processing, making the entire processing more efficient. It can realize automatic tool change, automatic tool setting, automatic measurement and other functions, reduce the time and workload of manual intervention, and improve the processing efficiency. And can be programmed to achieve mass production, further improve production efficiency. |

|

Flexibility |

It can process a variety of complex parts, including curved surfaces, bevels, special-shaped structures and various irregular shaped parts. The five-axis vertical machining center can be competent and has strong adaptability. |

|

Intelligentize |

Equipped with intelligent monitoring system, it can monitor the running state of the machine tool in real time, such as the temperature of the spindle, vibration, tool wear, etc., and analyze and process these data. When the machine tool is abnormal, it can send an alarm and provide fault diagnosis information in time, which is convenient for the operator to maintain and repair, reduce the downtime of the machine tool, and improve the reliability and stability of the equipment. It can be integrated with other equipment, such as robots, automated conveyor lines, etc., to form an automated production system to realize the automation and intelligence of the production process, support remote control and management, and the operator can remotely monitor, operate and manage the machine tool through the network. |

Application of five-axis vertical machining center:

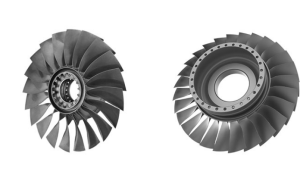

| Aerospace | |

| Five-axis vertical machining center is widely used in aerospace. It is used to process key components such as turbine blades and combustion chambers of engines to accurately shape complex shapes and ensure performance. In terms of aircraft structural parts, it can process wings, landing gear, fuselage frame, etc., to ensure strength and aerodynamic performance. It can also manufacture molds for aviation parts to achieve high-precision production. At the same time, it also plays an important role in parts repair and modification, such as repairing engine blades and extending their service life, providing strong technical support for aerospace manufacturing and helping the development of the industry. |  |

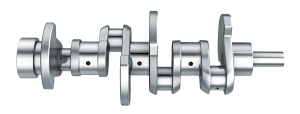

| Automobile manufacturing | |

| Five-axis vertical machining center plays a key role in automobile manufacturing. It can process complex parts such as engine cylinder block and crankshaft to improve accuracy and performance. It is used to manufacture components such as suspension systems for automotive chassis to ensure quality and reliability. |  |

| Mould Manufacturing | |

| The 5-axis vertical machining centre excels in the field of mould manufacturing. It can be used to process injection moulds, die-casting moulds and other types of complex moulds. It can accurately carve complex cavities and cores of moulds to ensure dimensional accuracy and surface quality. It is also easy to process the structure of slider and slanting top of moulds. It can complete multi-face machining by one clamping, reduce the working procedure and improve the efficiency of mould manufacturing. |  |

| Healthcare industry | |

| 5-axis vertical machining centres are widely used in the medical industry. They are used to manufacture orthopaedic implants, such as artificial joints and spinal internal fixators, to ensure fit to bones and enhance surgical results. In the dental field, processing dentures and dental implants to meet individual needs. We can also manufacture precision surgical instruments, like scalpels and endoscopic intervention instruments, to ensure safe and efficient surgery. In addition, in the development of medical devices, prototype parts can be manufactured quickly to verify innovative designs, helping to shorten the R&D cycle, reduce costs, and promote the continuous development of medical technology, providing strong technical support for the medical industry. |  |

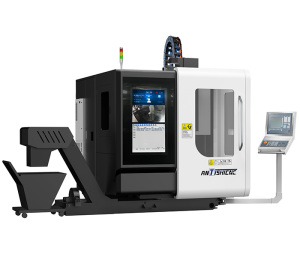

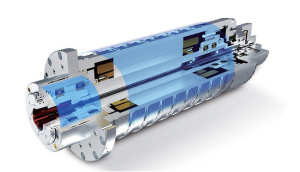

V5-630B is a high cost-effective 5-axis vertical machining centre manufactured by Shanghai ANTISHICNC Machine Equipment Co., Ltd. It adopts stable C-type structure, standard equipped with self-developed electric spindle and direct-drive cradle CNC rotary table, ATC circular tool magazine, which can achieve one-time clamping, 5-face machining/5-axis linkage high-efficiency machining of complex parts, and can meet the requirements of multi-variety and small batch multi-processing and flexible, compound machining of high-precision parts in the fields of automobile, electronics, transmission, engine, medical equipment and so on. It can meet the multi-process, flexible and compound machining of high-precision parts in the fields of automobile, electronics, transmission, engine, medical equipment, etc.

BC630 direct drive rotary table

Adopting high precision torque motor, zero transmission gap, no loss, equipped with high precision absolute encoder, constant temperature cooling with water cooler, with the advantages of high rigidity, high precision and high dynamic response. The working table adopts 8 14mm radial T-slots, with a maximum load of 500kg (horizontal) and 300kg (vertical).

Torque motor B-axis 2540Nm C-axis 700Nm

Positioning accuracy 6‘’

YRT bearing for high rigidity rotary table

Hydraulic locking B-axis 4000Nm C-axis 1400Nm

|

|

HSKA63/BT40 electric spindle

The electric spindle adopts high efficiency asynchronous internal motor with cooling nozzle at the end to cool the tool, which has the advantages of high speed, high precision and high dynamic response, and can achieve stepless speed regulation, and built-in high-precision encoder for directional quasi-stopping and rigid tapping.

High-efficiency copper rotor asynchronous internal motor

Bearing fixed pressure preload, can achieve ultra-high speed

Dynamic balance class G1

Low noise and thermal deformation

High dynamic rotary accuracy

|

|

The technical parameters are as follows:

| Item | Specifications | Unit | ||||

|

Turning- table |

Turning-table diameter | φ630 | mm | |||

| Max horizontal load | 500 | kg | ||||

| Max vertical load | 300 | |||||

| T-groove (number x width) | 8×14 | Unit×mm | ||||

|

Machining Range |

X-axis | 600 | mm | |||

| Y-axis | 450 | mm | ||||

| Z-axis | 400 | mm | ||||

| B-axis | -35~+110 | ° | ||||

| C-axis | 360 | ° | ||||

| The distance from

end face of spindle to working table |

Max | 550 | mm | |||

| Min | 150 | mm | ||||

|

Spindle |

Cone hole | HSKT63 | ||||

| Rated speed | 2000 | rpm | ||||

| Max speed | 12000 | rpm | ||||

| Output torque of motorized spindle (S1/S6) | 72/88 | N.m | ||||

| Output power of motorized spindle (S1/S6) | 15/18.5 | kW | ||||

|

Axis of coordinates |

Rapid movement | X-axis | 36 | m/min | ||

| Y-axis | 36 | |||||

| Z-axis | 36 | |||||

| Turning-table max speed | B-axis | 80 | rpm | |||

| C-axis | 800 | rpm | ||||

| X/Y/Z axis motor power | 2.2/2.2/2.2 | kW | ||||

| B/C axis motor power | 13.3/30 | kW | ||||

| B axis

|

Rated torque

|

2540 | N.m | |||

| c-axis

|

Rated torque | 360 | N.m | |||

|

Tool libary |

Type | Disc type | ||||

| Tool selection method | Two-way proximity selection | |||||

| Tool libary capacity | 24 | T | ||||

| Max tool length | 300 | mm | ||||

| Max tool weight | 8 | kg | ||||

| Max diameter of tool libary | Full tool | Φ80 | mm | |||

| Adjacent empty tool | φ150 | mm | ||||

| Weight | 7500 | kg | ||||

| Capacity | 60 | KVA | ||||

In summary, five-axis vertical machining centre is a wise choice for precision machining, in the future, with the continuous maturity of the technology and the gradual reduction of the cost, it is expected to be widely used in more fields, and promote the development of high quality in various industries, improve the accuracy, performance and reliability of the product, for the intelligent upgrading of the manufacturing industry and the development of innovation to provide a strong support.Our engineers will work with you to match the most suitable solution.