ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

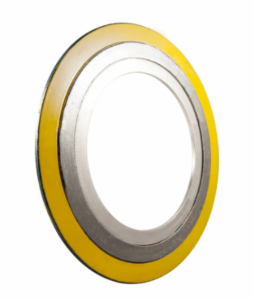

Stainless steel washers are important connectors in mechanical parts, and their quality and precision requirements are extremely high. CNC lathe machine, with their advanced technology and excellent performance, have become an ideal choice for processing stainless steel washers. When processing stainless steel washers on CNC lathe machine, the following aspects should be noted:

1.CNC lathe tool selection: Stainless steel has high hardness and toughness, and wear-resistant, high-temperature-resistant and good cutting performance tool materials, such as carbide tools, should be selected. The geometry of the tool should be reasonable, such as larger rake angles and back angles to reduce cutting force and cutting heat.

2.CNC lathe cutting parameters: The cutting speed should not be too high, generally between 80-150 m/min; the feed rate should be moderate, too large will easily lead to tool wear and reduced surface quality, too small will reduce processing efficiency; the cutting depth should be reasonably selected according to the size and precision requirements of the washer.

3.CNC lathe cooling and lubrication: Stainless steel processing will generate more heat, requiring sufficient cooling and lubrication. Water-soluble cutting fluid can be used, which can both cool and lubricate, reducing tool wear and thermal deformation.

4.CNC lathe clamping method: Make sure the gasket is firmly clamped to avoid displacement or vibration during processing. At the same time, pay attention to the clamping force not being too large to avoid deformation of the gasket.

5.CNC lathe precision control: Due to the large thermal expansion coefficient of stainless steel, pay attention to temperature control during processing to avoid thermal deformation affecting processing accuracy. After processing, precision testing should be carried out and processing parameters should be adjusted in time.

6.CNC lathe machine tool stability: Regularly maintain and service the CNC lathemachine to ensure the stability of various performances of the machine tool and provide a reliable foundation for processing.

|

|

Recently, a customer of Shanghai Ants Machine Equipment Co., Ltd. consulted about a CNC lathe machine for stainless steel 316/304 washers, with a maximum diameter of 100mm and a maximum thickness of 3.2mm. The material is stainless steel. The engineer successfully matched a CK6130 CNC flat bed lathe, and the customer was very satisfied.

Welcome to your consultation!

Keywords: lathe, CNC lathe, CNC flat bed lathe