ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

|

|

In the field of lathe manufacturing, cross roller bearings are important components for high-precision rotation, support and guidance, ensuring high precision and high accuracy during the processing. At the same time, CNC vertical lathes can also be used for production and processing. Shanghai ANTISHICNC Company introduces how CNC vertical lathes can process cross roller bearings:

1.Process of CNC vertical lathe processing cross roller bearings:

Turning the outer circle and end face: Clamp the bearing ring blank on the vertical lathe workbench, and after alignment, roughly turn the outer circle and end face, leaving a certain margin; then fine turn the outer circle and end face to ensure dimensional accuracy and surface roughness. The outer circle accuracy can be controlled within ±0.01mm, and the surface roughness reaches Ra0.8-Ra1.6μm.

Turning inner hole: For cross roller bearing rings with inner hole processing requirements, a boring tool is used for inner hole turning, first rough boring and then fine boring, to control the inner hole dimensional accuracy and cylindricity, and the cylindricity error can be controlled within ±0.002mm.

Raceway processing: Use forming tools or control tool paths through CNC programming to turn the raceway of the roller bearing to ensure the shape accuracy and surface quality of the raceway. The roundness error of the raceway can be controlled within ±0.001mm.

Grooving and chamfering: According to the design requirements, use a grooving tool to perform grooving processing to determine the size and depth of the slot; use a chamfering tool to chamfer the edge of the bearing ring to prevent edge burrs and stress concentration.

2.Advantages of CNC vertical lathe for processing cross roller bearings:

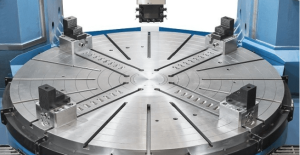

Vertical structure: Unlike traditional horizontal lathes, the spindle of vertical lathes is perpendicular to the ground, and the bearings can be placed horizontally.

Processing accuracy: The positioning accuracy of high-end CNC vertical lathes can reach ±0.005mm, and the repeat positioning accuracy can reach ±0.003mm.

Processing range: Depending on the model of cross roller bearings, the worktable diameter can range from 500mm to 5000mm, and the maximum processing height can reach 2000mm

Shanghai ANTISHICNC has a single-column CNC vertical lathe suitable for processing 2000mm diameter cross roller bearings, as shown below:

| Specifications | Unit | CK5123B×13/8 |

| Maximum turning diameter | mm | 2300 |

| Workbench diameter | mm | 2100 |

| Maximum workpiece height | mm | 1500 |

| Maximum workpiece weight | Ton | 8 |

| Table speed range | r/min | 1-80 |

| Machine weight (approx.) | Ton | 30 |

|

||

The processing stability of CNC vertical lathe is good. It reduces the error and scrap rate caused by human factors, thereby reducing production costs.

Welcome to your consultation!