ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

|

|

This month, Shanghai ANTISHICNC Company quoted a horizontal CNC lathe for processing motorcycle wheels for a Colombian customer. The CNC lathe has obvious advantages such as good overall rigidity, high processing accuracy, good precision retention, high reliability, easy maintenance and repair, and has a wide range of applications. This lathe is suitable for batch processing and production of motorcycle wheels, and can also be used in conjunction with other equipment. The technical solution is as follows:

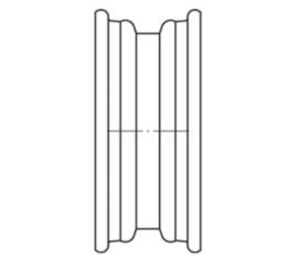

It is learned that the diameter range of the motorcycle wheels processed by the customer is 431mm-533mm, and the wheel width is about 35mm-77mm.

|

|

Shanghai ANTISHICNC Company engineer recommended TCK63E CNC horizontal inclined lathe machine to customers. The model reference is as follows:

| Specifications | Unit | TCK63E |

| Max. Swing over Bed | mm | Φ650 |

| Max. Swing over slide | mm | Φ470 |

| Center distance | mm | 1320 |

| Max.processing diameter of plate type work piece | mm | φ630 |

| Max. turning length | mm | 1000 |

|

||

TCK63E CNC lathe machine has the following advantages for processing customers’ motorcycle wheels:

1.High precision: TCK63E CNC horizontal lathe machine can control the size error within a very small range when processing wheels. For this customer’s motorcycle wheel processing, the diameter tolerance can be controlled within ±0.05mm to ensure good cooperation with tires, shafts and other components.

Moreover, the processing shape and position tolerance is small, which can effectively ensure the shape and position tolerances of the motorcycle wheel hub, such as roundness, cylindricity, verticality, etc. For example, the roundness error can be controlled within 0.03mm, making the motorcycle wheel hub rotate more smoothly and reducing vibration and noise.

2.High efficiency: Automated processing, 12-station turret realizes fast tool change, and can automatically complete multiple processes such as turning, drilling, boring, etc. of the wheel hub, reducing manual operation time and improving production efficiency. Compared with traditional lathes, it can save 30%-50% of processing time.

3.High flexibility. After our engineers set up the processing program, they can quickly adapt to the processing needs of wheels of different specifications, shapes and sizes without a large number of adjustments to equipment and fixtures. It is suitable for multi-variety and small batch production.

4.Stable processing quality: The cutting parameters of the TCK63E CNC lathe have been optimized and upgraded, which can make the surface roughness of the wheel reach Ra1.6-Ra3.2μm, reducing the workload of subsequent grinding and other processes.

Keywords: Lathe machine, CNC lathe machine, Horizontal CNC lathe, Wheel processing lathe machine