ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

|

|

CNC Vertical Lathe Processing Turbine Flanges Features:

Easy clamping: The turbine flange is large in size and heavy in weight. The vertical structure of the CNC vertical lathe allows the workpiece to be installed vertically based on the axis. The rotation of the worktable and the clamping of fixtures such as chucks can effectively avoid deformation due to the weight of the workpiece and ensure the stability and accuracy of clamping.

High machining accuracy: The CNC vertical lathe has good rigidity and strong precision retention. It can realize multi-axis linkage and accurately control the movement of the tool in different directions. It can perform high-precision machining on the inner and outer circles, end faces, keyways and other parts of the turbine flange to ensure that the dimensional accuracy and form and position tolerances of each part meet the requirements.

High machining efficiency: The vertical lathe worktable has a large load-bearing capacity and a wide speed range. It can be equipped with multiple tools for simultaneous machining. It can achieve efficient cutting through an automated control system, shorten machining time, and improve production efficiency.

CNC Vertical Lathe Processing Turbine Flanges Technology:

Rough machining: Use carbide tools to rough turn the blank, cut off most of the excess, and leave 0.5-1mm machining allowance for subsequent finishing. At the same time, pay attention to controlling the cutting parameters to avoid deformation or vibration of the workpiece due to excessive cutting force.

Fine machining: Replace sharp finishing tools, use smaller feed rate and cutting depth to ensure the surface quality and dimensional accuracy of the machining. For the sealing surface of the turbine flange, it is necessary to meet higher surface roughness requirements, which can be achieved through multiple passes and finishing.

Keyway machining: According to the size and accuracy requirements of the keyway, select a suitable keyway milling cutter, use CNC machining to ensure the position accuracy and dimensional accuracy of the keyway, pay attention to chip removal and cooling during machining to prevent tool wear and workpiece deformation.

Detection and correction: During the machining process, measuring tools such as calipers, micrometers, and three-coordinate measuring instruments are required for real-time detection, and deviations are corrected in time. After the machining is completed, a comprehensive inspection is required to ensure that the various indicators of the flange meet the design requirements.

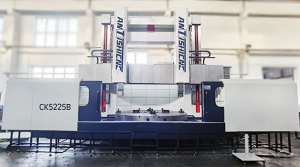

According to the function and requirements of the flange, the turbine flange design and planning must be carried out first, the size, shape and material of the processed parts must be determined, and the appropriate CNC vertical lathe model must be selected for precision processing. This month, a Rwandan customer from Shanghai ANTISHICNC Company consulted about processing a turbine flange with a diameter of 2000mm and a height of 1500mm. According to the customer’s requirements, our engineers customized a CK5225B CNC vertical lathe, as shown below:

| Specifications | Unit | CK5225B-16-15 |

| Maximum turning diameter | mm | 2500 |

| Table diameter | mm | 2250 |

| Maximum workpiece height | mm | 1600 |

| Maximum workpiece weight | Ton | 15 |

| Table speed range | r/min | 1~60 |

| Machine weight (approximately) | t | 37 |

| Machine footprint | mm | 9200*6800*4850 |

|

||

The processing stability of CNC vertical lathe is good. It reduces the error and scrap rate caused by human factors, thereby reducing production costs.

Welcome to your consultation!