ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

In today’s highly developed manufacturing industry, CNC lathe as a key production equipment, CNC lathe selection of the correct or not directly related to the production and operation of the enterprise, cost control, product quality and market competitiveness, is the development of enterprises in the crucial decision-making process. However, in the face of different types of CNC lathes, how to make a wise selection has become a problem faced by many enterprises and practitioners. In order to help you solve this confusion, the next by the Shanghai ANTISHICNC engineer for you to introduce the CNC Lathe how to choose type.

1. Clear processing needs is the key

First of all, a clear understanding of your processing tasks. Consider the size, shape, accuracy requirements of the machined parts and batch size and other factors. For example, if you mainly process large shaft parts, then you need to choose a CNC lathe with a large rotary diameter and bed length; and for precision parts processing with micron-level accuracy requirements, you need to pay attention to the spindle accuracy of the machine tool, the accuracy of the ballscrew and linear guide precision level.

2. Machine performance assessment is indispensable

The performance of the machine tool directly affects the machining effect. Focus on the spindle speed range, power and torque, which will determine the material and cutting process that the machine can adapt. At the same time, the accuracy and speed of the feed system is also an important indicator, high-precision ball screws and linear guides can ensure the machining accuracy and surface quality. In addition, the type of tool holder and tool change speed will also affect the productivity, electric tool holder is suitable for small and medium-sized batch production, hydraulic tool holder is more suitable for heavy cutting and high-volume machining.

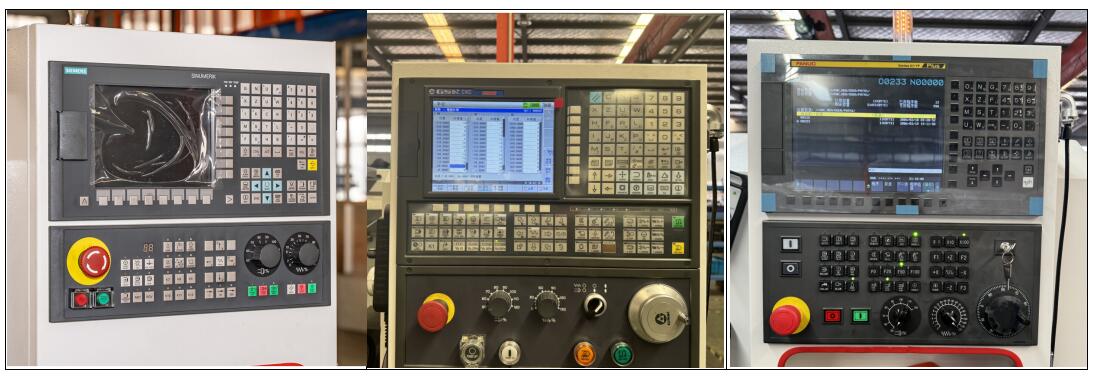

3. Control system determines the level of intelligence

Control system is the “brain” of CNC lathe, its brand and function is crucial. The control system of well-known brands usually has better stability and reliability, and can provide rich programming and operation functions, such as complex contour machining, tool radius compensation, macro programs. In addition, the user-friendliness and convenience of the operator interface will also affect the operator’s work efficiency and programming accuracy.

4. Stability and reliability should not be ignored

A stable and reliable CNC lathe can reduce downtime and improve productivity. Focus on the bed structure of the machine tool, high-quality cast iron bed has good shock absorption performance and rigidity. At the same time, understand the manufacturer’s manufacturing process and quality control system, choose a manufacturer with a good reputation and rich production experience, can provide you with more reliable equipment.

5. After-sales service to ensure worry-free production

In the selection process, after-sales service is also an important consideration. High-quality after-sales service includes timely technical support, rapid response to failures, adequate supply of spare parts. Ensure that the manufacturer has a perfect after-sales service network in your region, can be quickly resolved when the equipment problems, reduce the impact on production.

In short, the selection of CNC lathe is a comprehensive process, only through a comprehensive analysis and comparison, in order to select the most suitable for your production needs of CNC lathe, to provide strong support for the development of enterprises. We hope that the above introduction can help you in the selection of CNC lathes on the road less detour, choose the satisfactory equipment. You can send a picture to consult Shanghai ANTISHICNC, I believe that our company’s rich experience in the manufacture and use of CNC machine tools, can provide you with professional technical support.

Keywords: Lathe, CNC Lathe, CNC Liner Rail Lathe,Flat Bed CNC Lathe, Slant bed CNC Lathe, Heavy cutting Lathe