ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

Vertical milling machine has a spindle perpendicular to the worktable. During operation, the tool is installed on the vertical spindle, and the workpiece is processed by the rotation of the spindle and the longitudinal and transverse movement of the worktable on the horizontal plane.

The spindle of the horizontal milling machine is parallel to the worktable. During processing, the rotation axis of the tool is horizontal, and the workpiece is processed by the movement of the worktable (including longitudinal and transverse movement and rotation of the worktable) and the rotation of the tool.

Structural differences

1.Spindle direction

Vertical milling machine: Its spindle is set perpendicular to the worktable. This structure allows the tool to perform cutting movement in the vertical direction. When processing a plane, the tool feeds vertically downward, which is more intuitive and convenient.

Horizontal milling machine: The spindle is parallel to the worktable. After the tool is installed on the spindle, the cutting movement is in the horizontal direction, which is more suitable for some workpieces that need to be processed on the side.

2.Worktable design

Vertical milling machine: The worktable generally moves in both vertical and horizontal directions on the horizontal plane, mainly used to adjust the relative position of the workpiece and the tool on the plane, and facilitate the processing of planes, grooves, etc.

Horizontal milling machine: In addition to being able to move vertically and horizontally on the horizontal plane, the worktable is often equipped with a turntable. The turntable can rotate the worktable within a certain angle range, so that workpieces with complex curves such as spiral grooves can be processed

Types of workpieces suitable for processing

Workpieces suitable for processing by vertical milling machines

Mainly used for processing planes, grooves, steps, etc. In the mold manufacturing industry, it is used to process the plane parts of the mold cavity and core; in the machining workshop, it is used to process the planes of various mechanical parts, such as the end faces of flanges and the planes of box parts; it can also be used to mill grooves of various shapes, such as straight grooves, T-shaped grooves, etc.

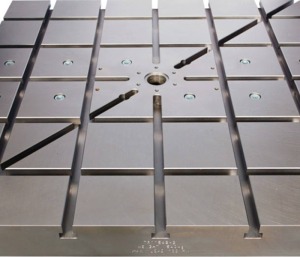

Planar parts:like flat parts in machining, such as the worktable of a machine tool. Using a vertical milling machine, the tool mills the surface of the workpiece vertically downward, which can efficiently process a flat plane. Moreover, by adjusting the movement of the worktable, it is convenient to process various shapes of plane contours, such as rectangles, circles, etc.

End planes and grooves of disc parts:for example, end plane processing of gear blanks and keyway processing on the end face. The vertical milling machine can align the tool vertically with the end face of the disc part for milling. For milling grooves on the end face, the processing can also be completed accurately by controlling the movement of the worktable.

|

|

|

Workpieces suitable for processing by horizontal milling machines

Horizontal milling machines are suitable for processing parts of various shapes such as shafts, discs, and sleeves. In mechanical manufacturing, it is often used to process keyways and splines of shaft parts, such as keyways on automobile drive shafts; it can also be used to process the sides of disc parts, such as the sides of gear blanks; it can also be used to process various spiral structures, such as the spiral grooves of twist drills, the tooth grooves of helical gears, and other complex-shaped workpieces.

Shaft parts:For example, horizontal milling machines can play a good role in the side milling of long shaft parts. Like the drive shaft of an automobile, it is necessary to mill the keyway on its cylindrical surface. The horizontal milling machine can enable the tool to cut the side of the shaft horizontally to ensure the accuracy and surface quality of the keyway.

Parts with spiral grooves:such as the spiral groove processing of twist drills. Due to the rotation function of the horizontal milling machine worktable, the spiral groove can be accurately processed with the dividing head. By adjusting the rotation angle of the worktable and the feed amount of the tool, cutting according to the law of the spiral line can meet the processing requirements of the spiral groove.

|

|

|

Recently, Shanghai ANTISHICNC received an inquiry from a Russian customer about a vertical milling machine. According to the customer’s needs, we matched the following model parameters for the customer:

| Specification | Unit | XQ5032C |

| Table size | mm | 1370*320 |

| Table Travel (X/Y/Z) | mm | 1000/380/400 |

| Distance from spindle nose to work surface | mm | 35-435 |

| Spindle hole taper | — | 7:24 ISO40 |

| Rapid speed of table (X/Y/Z) | mm/min | 1335/1335/1000 |

| Table feed (X/Y/Z) | mm/min | XY:30-830 Z23-625 |

| T-slots(NO./Width/Pitch) | mm | 3/14/80 |

| Spindle speed range | r/min | 12steps 35-1500 |

| Stroke of spindle quill | mm | 70 |

| Distance between spindle axis and column guide way | mm | 285 |

| Swivel angle of Vertical milling head | — | ±30° |

| Main motor power | kw | 3 |

| Torque of X/Y/Z axis AC servo motor | N.m | 15 |

| Overall size | mm | 1820*1680*1810 |

| Net weight | kg | 1650 |

|

||

If you also need a suitable milling machine, welcome to consult Shanghai ANTISHICNC. We are a senior supplier of metal machining equipment, with rich experience in manufacturing and using mechanical equipment, and can provide you with professional technical support.

Keywords:Milling machines, vertical milling machines, horizontal milling machines