ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

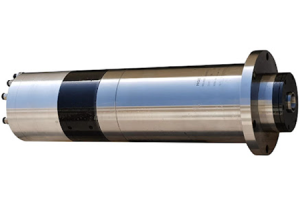

Electric spindle is an indispensable part of modern high-speed machine tools. It is a technology that integrates the machine tool spindle and the spindle motor in the field of CNC. As the machine tool industry continues to develop towards high speed, high efficiency and high precision, the spindle of CNC machine center has more applications, and the electric spindle also plays an important role in CNC machine center:

1. Improve the processing efficiency of CNC machine center:

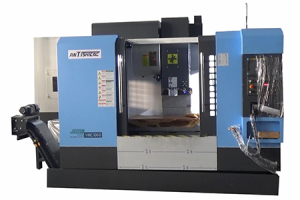

The function of CNC machine center is to improve the concentration of processes and minimize the number of repeated clamping of parts, thereby greatly improving production efficiency and machining accuracy. This function requires that the CNC machine center has multiple tools or even multiple spindles. More rotating parts require more bearings; the accuracy requirements for tool and workpiece positioning require higher precision bearings to cooperate. In order to improve production efficiency, the new generation of CNC machine centers are developing towards ultra-high speed, and high-speed machining often requires the cooperation of new functional components, such as: Shanghai ANTS Machine Equipment Company’s high-speed electric spindle, especially the vertical machine center, can reach the high speed requirement of 15000RPM-20000RPM. At the same time, this also puts forward higher requirements on the maximum speed, rotation accuracy, vibration and noise of the supporting bearings.

2. More precise machining:

Precision is the eternal pursuit of the processing industry. The speed stability of the electric spindle is very high, and it can maintain a constant speed during long-term processing. This is crucial to ensure machining accuracy, especially when performing precision machining, where even slight speed fluctuations may affect the machining quality. For example, when machining high-precision molds, the stable speed of the electric spindle can ensure that the dimensional accuracy of the machined mold reaches a very high standard.

3. Environmental protection

The electric spindle has low vibration and low noise. Low vibration can reduce vibration errors during machining, thereby improving machining accuracy. Low noise provides operators with a relatively quiet working environment, which is conducive to improving work efficiency and quality.

– For example, when processing some parts with extremely high surface quality requirements, the low vibration characteristics of the electric spindle can ensure that the processed surface is smooth and flat without chatter marks.

4. Save space and energy

The electric spindle integrates the motor and the spindle together, with a compact structure and small space occupation. This makes the overall structure of the machining center machine more concise, reduces the footprint of the machine tool, and provides greater flexibility for workshop layout. For example, in some workshops with limited space, machining centers using electric spindles can better meet production needs. The electric spindle is highly efficient and can effectively convert electrical energy into mechanical energy, reducing energy loss. Compared with traditional mechanical spindles, electric spindles can save a lot of energy during operation.

Electric spindles are used in various industries, various CNC machine tools, such as machining centers, milling machines, drilling machines, etc., for metal cutting, mold processing, aerospace parts processing, etc.

Keywords: CNC machine center, CNC machine center electric spindle, vertical machine center,VMC machine