ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

Recently, our company received an enquiry, there is a Fire fighting atomizing nozzle manufacturers to find us, he wanted to process the requirements of us to provide the ability to process the maximum diameter of 30cm brass and stainless steel nozzles, after our engineers to understand the communication, matched with a suitable milling and turning composite, able to meet his processing needs.

A fire fogging nozzle is a type of nozzle that is capable of converting fire fighting water or extinguishing agent into tiny droplets. These droplets typically have a high specific surface area and are more effective in interacting with flames and hot smoke during the fire fighting process to extinguish the fire.

| Electrical equipment sites |

| Such as data centres, distribution rooms, etc. These places are very sensitive to the conductivity of water, atomised spray nozzles spray droplets can avoid damage to equipment due to conductivity, and at the same time can effectively extinguish electrical fires. |

| High-value goods storage places |

| Like museums, libraries, etc., the use of atomised spray nozzles can be used to extinguish fires while reducing water damage to cultural relics, books and other valuable items. |

| Places where flammable and explosive liquids are stored and used |

| For example, petrol stations, oil depots, chemical warehouses, etc., atomised nozzles can control liquid fires by covering and absorbing heat through fog droplets and can avoid liquid flow and spreading of fires due to large amounts of water. |

|

Complex shape machining

|

Contour moulding: The shape of a Fire fighting atomizing nozzle is usually complex and comes in a variety of shapes. Mill-turn machining allows the precise contouring of the sprinkler head through a combination of turning and milling processes. For example, the nozzle body part may be cylindrical, with various shapes of bumps, grooves or threads, mill-turning machine tools can complete the processing of these different shapes in a single clamping, to ensure that the dimensional accuracy and shape accuracy of each part. |

| Internal structure machining: For complex structures inside the nozzle, such as special channels and small holes in the atomising core, mill-turn machining also has advantages. It can use the milling function to machine high-precision internal channels, and turn the internal cylindrical part to ensure the concentricity and surface finish of the internal structure. This integrated machining reduces errors that may occur due to multiple clamping and equipment changes, and improves the machining quality of the nozzle’s internal structure. | |

| Satisfaction of high-precision machining requirements | Dimensional accuracy control: The dimensional accuracy of a Fire fighting atomizing nozzle is critical to its performance. During the mill-turn machining process, the individual dimensions of the nozzle can be controlled within very tight tolerances through precise programming and advanced CNC systems. For example, the interface dimensions (e.g. thread size) of the nozzle must be precise to ensure a good connection with the fire fighting pipe; the diameter and depth of the small holes of the atomising core also need to be processed with high precision, as these dimensions have a direct impact on the atomisation effect. Mill-turn machining can meet these high-precision dimensional requirements, to ensure that the quality and performance of the nozzle is stable. |

| Surface quality enhancement: good surface quality can prevent the nozzle from corrosion, clogging and other problems in the process of use. Turning and milling composite machine tools can be used to obtain a high surface finish by selecting appropriate tools and cutting parameters. For the external surface of the nozzle, high surface finish can reduce the adhesion of impurities; for the internal channels and small holes, a smooth surface can prevent the fire extinguishing agent or water from generating excessive resistance during the flow process, ensuring that the nozzle works properly. | |

| Increased material adaptability and machining efficiency | Multi-material machining: Fire fighting atomizing nozzle can be made of a variety of materials, such as brass, stainless steel and so on. Turn-mill compound machining centre can adapt to the machining characteristics of these different materials. For brass material, turning and milling composite machine tool can be based on its softer characteristics, select the appropriate cutting speed and feed to avoid material deformation; for stainless steel and other high hardness materials, can also be achieved through reasonable tooling and machining parameters, to achieve high efficiency machining. |

| Reduce machining time: As mill-turn compound machining integrates turning and milling processes together, it reduces the number of transfers and clamping of workpieces between different machine tools. For example, in traditional machining methods, the nozzle may need to be machined first in the lathe for the shape, and then sent to the milling machine to machine the internal structure, which has a long turnaround time in between. The milling and turning composite processing can complete most of the machining process on a single device, greatly reducing the processing cycle, improve production efficiency, for the fire nozzle atomised spray nozzle such as a large demand for products, can effectively reduce production costs. | |

| Advantages of individualisation and small batch production | Meeting different design requirements: Different firefighting scenarios may require atomised spray nozzles of different specifications and designs. Turn-mill machining can be easily customised to meet individual customer requirements. Whether it is the external dimensions of the nozzle, the atomisation method (e.g. changing the structure of the atomising core) or the type of interface, this can be achieved by adjusting the machining process and programming. |

| Flexibility in small batch production: In the fire protection equipment industry, it is sometimes necessary to produce small batches of special specification atomised spray nozzles for specific projects. Turn-mill machining centres are ideally suited to this low-volume production model, as they do not require the large-scale equipment adjustments and tooling changes of conventional production lines. With quick programming and equipment parameter adjustments, small batch production can be started to meet the diverse needs of the market. |

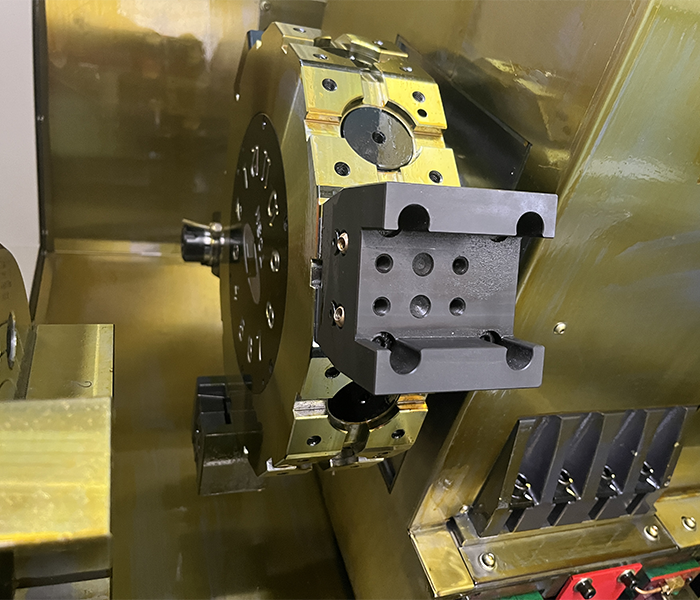

According to the customer’s needs, we finally matched TCK50Y/500 mill-turn CNC lathe.

TCK50Y/500 adopts 30° whole slanting bed structure, equipped with high-precision pre-loaded Taiwan linear roller guideway, the machine tool has high positional accuracy, smooth chip removal, and is suitable for high-speed and high-precision machining.

Adopting high-precision spindle bearing set and spindle with precision assembly and dynamic balance test to ensure high precision, low noise and strong rigidity of spindle.

The turret method is adopted to ensure fast tool change speed and high positioning accuracy.

X, Z direction feeding adopts servo motor through high torque and low inertia elastic coupling and screw direct connection to ensure positioning accuracy and repeat positioning accuracy.

Domestic hydraulic chuck is adopted, hydraulic tailstock is manually adjusted and locked, and hydraulic piston is used to tighten the workpiece for machining.