ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

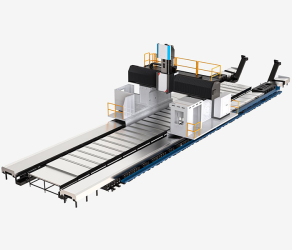

| Moving column gantry machining center | Fixed-column gantry machining center |

|

|

Both moving-column gantry machining centers and fixed-column gantry machining centers have a variety of processing functions such as milling, boring, drilling, and tapping. They can perform plane milling, contour milling, cavity milling, boring, drilling, and tapping on various work-pieces to meet the processing needs of parts of different shapes and technological requirements. The structure has the form of a gantry frame. This structure makes them suitable for processing large and heavy work-pieces and can withstand large cutting forces.,

So what is the difference between a moving column gantry machining center and a fixed column gantry machining center:

| Features | Moving column gantry machining center | Fixed column gantry machining center |

| Structural features | The workbench is fixed and the gantry frame can be moved. The gantry frame composed of double columns and top beams can be moved along the guide rail above the workbench. The head-stock with a large cross-section structure of a square ram is usually used, which has high rigidity and good stability at low speed. | The column is fixed, and according to whether the beam moves, it can be divided into two types: fixed beam type and moving beam type.The fixed beam type beam is fixed, and the workbench moves or rotates; the moving beam type beam can be moved up and down, and the workbench moves back and forth. |

| Working principle | The CNC system controls the movement of the gantry above the workbench and the movement of the spindle on the gantry, so that the tool can accurately locate the machining position of the work-piece in three-dimensional space, and realize a variety of machining operations on the work-piece. | The fixed beam type is the movement of the workbench with the work-piece, so that the workpiece moves relative to the fixed beam and the tool to complete the processing; the moving beam type is to adjust the height and position relationship between the tool and the workpiece through the movement of the beam up and down, combined with the movement of the workbench back and forth, to achieve the surface of the workpiece of different heights and positions for processing. |

| Processing range | The movement of the gantry frame enables the machine tool to adapt to the processing of workpieces of different sizes and shapes. It has more advantages for the processing of large structural parts, polyhedron workpieces, etc., which can reduce the number of workpiece clamping and improve processing efficiency, such as ship propellers, large molds, etc. | The fixed beam type is suitable for machining small and medium-sized parts with high precision requirements and relatively simple shapes, such as small injection molds in mold manufacturing; the moving beam type is suitable for machining parts with large heights and complex shapes, such as aircraft wing girders. |

| Accuracy retention | Due to the movement of the gantry, the accuracy retention of the machine tool may be affected to a certain extent, but through the use of high-precision guide rails, screws and other transmission components, as well as advanced error compensation technology, the accuracy loss can be controlled within a small range, and the machining accuracy requirements of most parts can still be met. | The fixed-column fixed-beam structure is relatively simple, and the components are fixed, and they are less affected by external forces during the processing process. Therefore, it has good accuracy retention and can ensure machining accuracy stably for a long time. It is suitable for parts processing with extremely high accuracy requirements, such as some key parts in the aerospace field. |

| Space utilization | The workbench is fixed, and when large workpieces are not processed, the gantry can be moved to a suitable position, saving working space and facilitating the layout and operation of other equipment in the workshop. | Since the fixed beam structure has fixed beams and columns, it is relatively not flexible enough in the use of space, especially when processing large workpieces, it requires a lot of installation and operation space. |

| Equipment cost and maintenance difficulty | The structure is relatively complex, the manufacturing and maintenance costs are high, and the technical level requirements of the operators are also high, but its processing efficiency and flexibility make it cost-effective in the field of large and complex parts processing. | The fixed-column fixed-beam type has a simple structure, relatively low manufacturing cost, and easy operation and maintenance. It is suitable for small and medium-sized enterprises and occasions where the machining accuracy requirements are not particularly high; the fixed-column moving-beam type increases the moving function of the beam, and its cost and maintenance difficulty are between the fixed-column fixed-beam type and the moving-column type. |

Shanghai ANTISHICNC is a professional manufacturer of gantry machining center, we have rich experience in production and processing,can recommend the right gantry machining center for your product, and give the right advice on the use of the gantry machining center, can provide you with professional technical support. If you need gantry machining center, welcome to contact Shanghai ANTISHICNC.

Tags:Gantry machining center, Gantry milling machine,Machine center,Gantry machine center