ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

I.The number of threads in ordinary lathes has the following common meanings:

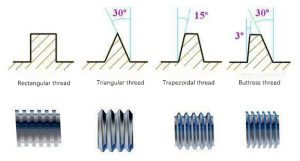

1.Number of screw threads

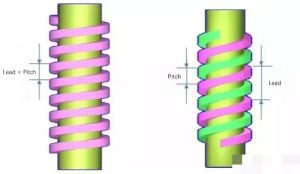

Meaning: The screw of an ordinary lathe is an important component used for turning threads and other processing. The number of threads on the screw refers to the number of spiral lines distributed along the axial direction on the screw surface. The number of screw threads determines the transmission ratio and feed rate of the lathe when turning threads. The number of screw threads is usually fixed, and the common ones are single-line threads and multi-line threads.

Function: For each turn of the single-line screw, the tool moves a pitch distance axially; for each turn of the multi-line screw, the distance the tool moves axially is equal to the pitch multiplied by the number of lines, and this distance is called the lead. Multi-line screws can enable the tool to obtain a greater feed speed at the same spindle speed, thereby improving the thread processing efficiency, and are often used to process large pitch threads or multi-start threads.

2.The number of threads of the processed workpiece

Meaning: refers to the number of spiral threads formed on the surface of the processed workpiece. According to the number of spiral threads, it can be divided into single-thread and multi-thread.

Function: Single-thread is mainly used for connection and fastening, such as common bolts and nuts; multi-thread is often used in occasions that require fast transmission or large power transmission due to its large lead, such as the screw nut pair in some mechanical transmission.

3.Number of threads on the lathe nameplate

Meaning: The nameplate of an ordinary lathe will indicate the number of threads that the lathe can process, including metric threads, imperial threads, and modulus threads.

Function: It reflects the lathe’s ability to process threads of different specifications and types, helping the operator to select a suitable lathe according to the processing requirements, and adjust the lathe’s transmission mechanism and parameters according to the instructions on the nameplate to achieve the processing of different threads.

4.Number of threads of gears in the pulley box

Meaning: The pulley box is part of the transmission system of an ordinary lathe, used to change the transmission ratio of the lathe to meet different processing requirements. The gears in the pulley box also have threads, and the number of threads here generally refers to the number of teeth on the gears.

Function: By selecting gears with different numbers of teeth for combination, the transmission ratio between the lathe spindle and the lead screw can be changed, thereby achieving the purpose of processing threads of different pitches.

II. The influence of the number of threads in ordinary lathes on the workpieces

1.Connection strength and sealing

More threads: In connection workpieces, such as the combination of bolts and nuts, more threads means an increase in the length of thread engagement, which can make the connection more secure, withstand greater axial tension and torque, and reduce the possibility of loosening due to factors such as vibration. In some applications such as pipeline connections that require sealing, more threads can increase the reliability of the seal and reduce the risk of leakage.

Fewer threads: When the number of threads is small, the connection is relatively weak. When subjected to greater external forces, it may be more prone to loosening, slipping, and other problems, and the sealing performance is relatively poor.

2.Processing difficulty and efficiency

More threads: The tool needs to perform more reciprocating cutting movements on the workpiece, and the processing time will increase significantly. Due to the increase in the number of cutting times, the wear on the tool is also more serious, and the tool needs to be replaced or sharpened more frequently. During the processing process, the lathe transmission system and the operator’s skills are also required to be higher, because the depth of each cutting, feed rate and other parameters must be accurately controlled to ensure the accuracy and quality of the thread.

Fewer threads: The time required for processing is relatively short, the tool wear is relatively small, the processing process is relatively simple, the skill requirements for the operator are relatively low, and the processing efficiency is high.

3.Movement characteristics of workpieces

More threads: In some transmission workpieces, such as screw and nut pairs, if the number of threads is large, it means that the screw needs to rotate more times at the same axial movement distance. This will make the motion transmission smoother, the transmission accuracy higher, and more precise displacement control can be achieved, but it will also reduce the speed of movement.

Fewer threads: Under the same number of screw rotations, the axial movement distance of the nut is larger, and a faster movement speed can be achieved, but the smoothness and accuracy of the movement are relatively low.

4.Pitch and lead

More threads: For multi-start threads, the more threads, the larger the lead. When turning, the tool needs to move a larger distance per unit time, the lathe feed system needs to provide a higher feed speed, and the performance requirements of the lathe are higher.

Fewer threads: The pitch and lead are relatively small, the burden on the lathe feed system is relatively light, and it is easier to achieve stable processing.If you have any questions about the above, please contact Shanghai ANTISHICNC. If you also need a suitable lathe, please consult Shanghai ANTISHICNC. We are a senior supplier of metal machining equipment, with rich experience in manufacturing and using mechanical equipment, and can provide you with professional technical support.

Keywords: Lathe, Universal lathe, Lathe machine