ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

Double spindle lathe is a more advanced machine tool equipment, its core feature is equipped with two independent operation of the spindle. These two spindles can carry out machining work at the same time, or carry out different processes, which greatly improves the machining efficiency.

Double spindle lathe usually has a high degree of automation. It can precisely control the movement trajectory, rotational speed, feed speed and other parameters of the two spindles through the CNC system to realize high-precision machining of complex parts.

Advantages of dual-spindle lathes:

Improvement of productivity: It can process two workpieces at the same time, or clamp a large part with two spindles, realize tool change, and greatly save processing time. When machining the same parts, its efficiency can be doubled compared with single spindle lathe; when machining different parts, it can greatly shorten the turnover of parts between processes.

Ensure machining accuracy: dual-spindle can work together, so that the vibration and error in the machining process is better controlled, and its CNC system can also more accurately control the movement of the two spindles and the cutting process. In addition, in many cases a single part can be machined in its entirety, eliminating the need to transfer workpieces between machines and thus reducing the accumulation of errors caused by changes in positioning references.

Reduced costs: Cost reductions of up to 40% can be achieved, e.g. in combination with perfected high-performance tools that are fine-tuned to the machining task, production times can be significantly shortened, reducing the cost per part; production, operating and management costs for fixed assets are also reduced due to the reduction in the number of machines, fixtures and shop floor space required.

Extended service life: The production machines have tried and tested robust automatic workpiece changers for extended service life.

Relatively simple operation: the overall operation is more intelligent and the technical requirements for operators are relatively lower.

Double spindle lathe is widely used in automotive, aerospace, machinery and other manufacturing industries to process shafts, disks and other precision parts, to meet the requirements of efficient and high-precision production.

If you have the need for machining complex parts with high precision requirements, ANTISHICNC CTX200S high-speed dual-spindle turning center can be a reference for you.

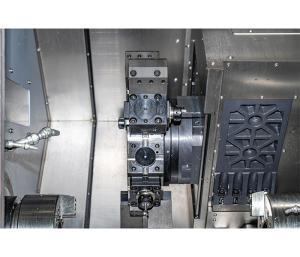

The CTX200S is a dual turret, dual spindle CNC lathe with a fixed spindle box. Compact, versatile and fast, it allows combined turning, milling and drilling of small-sized parts.

Features:

1.The workpiece clamped one time could finish all processing steps.This machine tool has the high speed, the high precision, and the strong composite processing ability.

2.It can process various large and long workpieces.

3.It can be widely used in various industries such aviation, energy, shipbuilding, and medical treatment. The modular concept and the highly versatile options provide a wide range of machining possibilities, and achieve machining from universal turning to complex parts complete machining.

4.Taiwan roller type linear guide.

5.Higher speed spindle unit.

6.High power Y-axis motor.

7.Embedded lubrication system.

8.High rigidity integral inclined bed.

| Specifications | Units | CTX200S | |

| Max. Swing over bed | mm | Φ700 | |

| Swing over cross slide | mm | Φ300 | |

| Maximum shaft length | mm | 450 | |

| Maximum disk processing diameter | Φ300 | ||

| Maximum turning length | mm | 450 | |

| Spindle | Spindle end type | A2-6 | |

| Spindle through hole diameter | mm | Φ66 | |

| Bar diameter | mm | Φ50 | |

| Hydraulic chuck | Inch | 8 | |

| Hydraulic chuck tie rod through hole | mm | Φ50 | |

| Spindle taper hole taper | No | MT6# | |

| Spindle limit speed | rpm | 4000rpm | |

| Sub-spindle

|

Spindle end type | A2-6 | |

| Spindle through hole diameter | mm | Φ66 | |

| Bar diameter | mm | Φ50 | |

| Hydraulic chuck | Inch | 8 | |

| Hydraulic chuck tie rod through hole | mm | Φ50 | |

| Spindle taper hole taper | No | 70/1:20 | |

| Spindle limit speed | rpm | 4000rpm | |

| Tool | Model | TYCSDY80HP-12T

Powered turret |

|

| Tool holder model | BMT55 | ||

| Y axis travel | mm | ±45 | |

| Power motor torque | N.m | 15 | |

| Y-axis motor torque | N.m | 6 | |

| Lead screw model

|

X direction | 3210 | |

| Z direction | 4010 | ||

| Z2 direction (sub-spindle) | 4010 | ||

| Guide rail model | X direction | RGH35HA | |

| Z direction | RGH45CA | ||

| Z2 direction (sub-spindle) | RGH45CA | ||

| X/Z/Z2 motor torque | N.M | 15/15/15 | |

| X/Z/Z2 direction rapid movement speed | m/min | 18/18/18 | |

| X-direction travel | mm | 200 | |

| Z-direction travel | mm | 520 | |

| Minimum setting unit | mm | 0.001 | |

| Main motor power | KW | 11 | |

| Total power | KW | 32 | |

| Machine tool net weight | Kg | 4200 | |

| Overall dimensions (length × width × height) | mm | 4250*2000*2200 | |

If you have the need to process workpieces with complex shapes and high precision requirements, welcome to consult Shanghai ANTISHICNC. We have rich experience in manufacturing and and application of dual-spindle turning center, and can provide you with professional technical support.