ANTISHICNC CNC Turning Milling Machines,CNC Lathes

ANTISHICNC CNC Turning Milling Machines,CNC Lathes

Swiss-type lathe is an advanced machine tool equipment. It processes parts through the rotation and movement of the spindle and the precise up, down, left and right movement of the tool. It also supports multiple feedings and often uses a center guide sleeve to ensure high precision of processing. Its structure arranges tools in two axes, which greatly reduces the processing cycle time and tool exchange time. It has excellent functions such as multiple tool table overlaps and is also equipped with an automatic feeding device to achieve a fully automated production mode for a single machine tool. With such working principles and structural characteristics, Swiss-type lathes occupy an important position in the field of precision machining, and efficiently create high-quality parts for many industries such as aerospace, medical equipment, etc., which has strongly promoted the manufacturing industry to move towards a higher level of precision and advancedness.

Among them, Swiss-type lathes are widely used in the processing of medical devices, such as tooth nails, bone nails, tool rods, etc.

| Bone nail | Tooth nail |

|

|

| Screw | Dental Materials |

|

|

Sample display

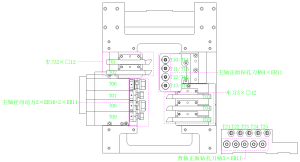

For the medical device field, our best-selling model G205E can meet most processing needs.

| Description | Unit | Swiss-type lathes G205E | |

| Main Spindle | Single feeding stroke (spindle) | mm | 80 (optional: 120/140) |

| Max working speed (spindle/sub-spindle) | rpm | 8000 | |

| Max rotation diameter (spindle/sub-spindle) | mm | ¢20 | |

| Minimum number of divisions (spindle/sub-spindle) | ° | Stepless | |

| Spindle hole diameter (spindle/sub-spindle) | mm | ¢22 | |

| Turning tool | Number | ea | 5 (T01/T02/T03/T04/T05) |

| Size | mm | 12×12 | |

| Front drilling tool | Number | ER | 4*ER11(T10/T14)(T11/T15)

(T12/T16)(T13/T17) |

| Max drilling diameter | mm | ¢8 | |

| Max tapping diameter | mm | M6 | |

| Spindle radial power tool (front) | Number | ER | 2×ER11+2×ER16

(T07/T09+T06/T08) |

| Max speed | rpm | 5000 | |

| Max drilling diameter | mm | ¢8 | |

| Max tapping diameter | mm | M6 | |

| Max milling tool diameter | mm | 30 | |

| Back drilling tool | Number | ER | 5×ER11(T21/T22/T23/T24/T25) |

| Max drilling diameter (back) | mm | ¢8 | |

| Max tapping diameter | mm | M6 | |

| Motor | Spindle/sub-spindle motor | KW | 3.7/2.2 |

| Spindle radial power tool motor (front) | KW | 1 | |

| Servo axis motor | KW | (X1, Z1, Y1, X2, Z2): 1 | |

| Lubrication pump motor | KW | 0.1 | |

| Cooling pump motor | KW | 0.35 | |

| Rapid feed speed | m/min | 25 | |

| Other | Cooling box capacity | L | 130 |

| Lubrication device capacity | L | 3 | |

| Center height | mm | 1050 | |

| Overall dimensions (length × width × High) | mm | 2100×1100×1800 | |

| Machine weight | KG | 2680 | |

| Machine power | KW | 12.5 | |

| CNC control system | Standard | SYNTEC 220TB | |

For different products, we will also recommend other models or provide customized services according to actual processing requirements. If you have similar medical device production needs, please send us drawings for consultation.